Edge Banding

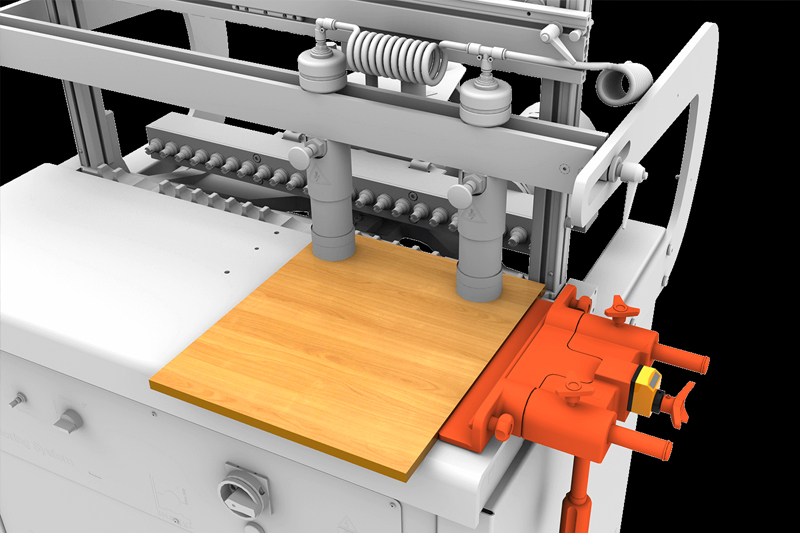

Benefits of Vacuum Press in Woodworking

- Uniform Pressure Distribution: The vacuum press applies uniform pressure across the entire surface of the workpiece, ensuring even clamping and adherence of the veneer or laminate.

- Versatility: It can be used for a variety of woodworking applications, including veneering, laminating, and shaping curved parts.

- Ability to Handle Complex Shapes: Because it uses a flexible membrane, it can conform to complex shapes and contours, allowing for the pressing of curved or irregularly shaped workpieces.

- Reduced Risk of Damage: Unlike traditional clamping methods that can apply uneven pressure and potentially damage delicate or irregular surfaces, the vacuum press exerts consistent pressure without the risk of marring the workpiece.

- Efficiency: Vacuum pressing can often be faster than traditional clamping methods since it doesn't require the time-consuming process of tightening clamps individually.

- Less Labor Intensive: Once set up, a vacuum press can require minimal supervision, allowing woodworkers to focus on other tasks while the press does its job.

- High-Quality Results: The even pressure distribution and precise control offered by vacuum press systems often result in high-quality, professional-looking finishes.

Overall, a vacuum press membrane shutter can be a valuable tool in the woodworking shop, offering efficiency, versatility, and high-quality results for a variety of applications.