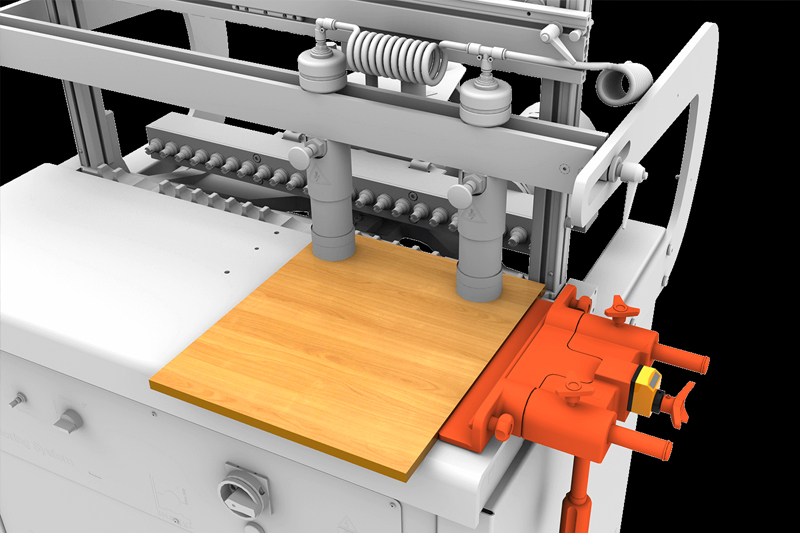

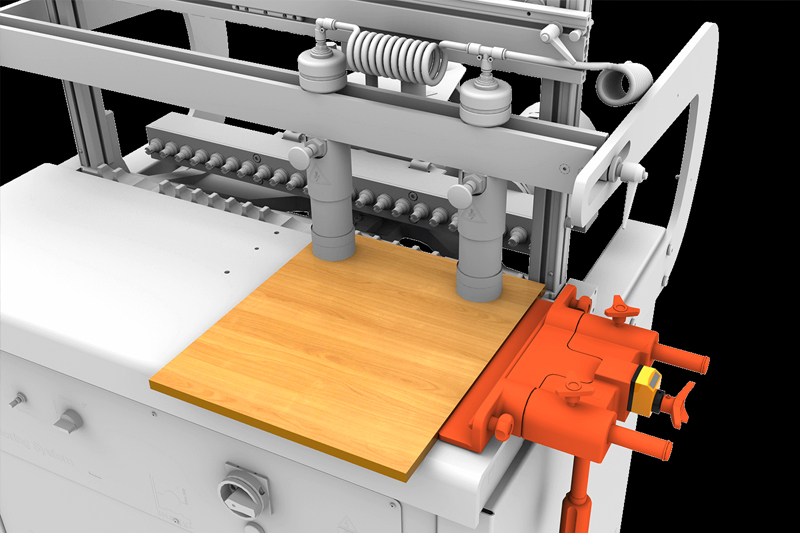

Boring

Benefits of Multi-Boring Machines in Woodworking

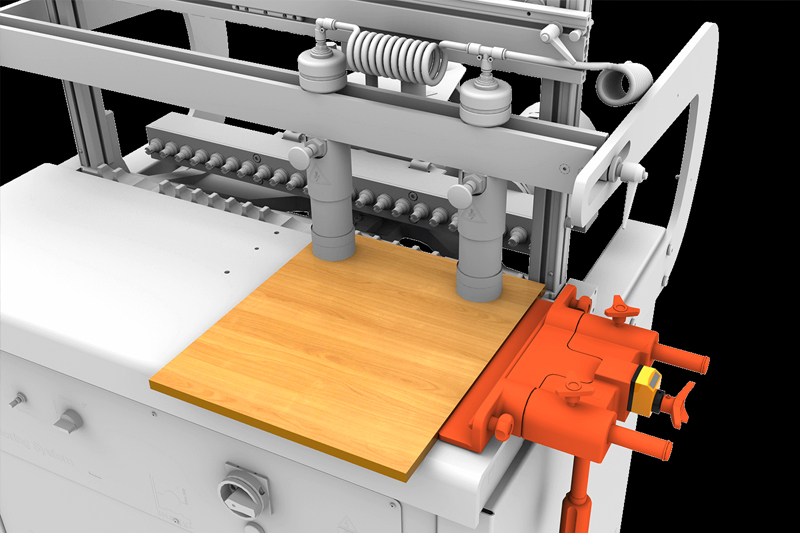

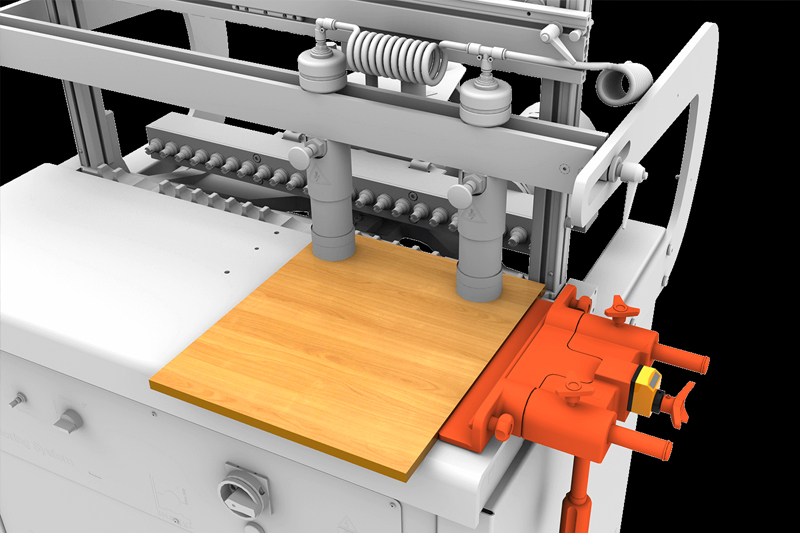

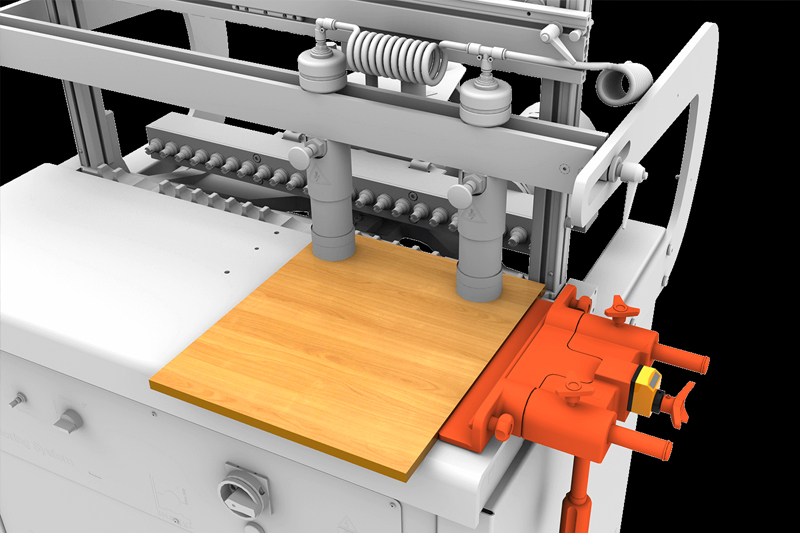

- Increased Efficiency: Multi-boring machines can drill multiple holes simultaneously, significantly reducing production time compared to drilling each hole individually. This efficiency can lead to higher productivity and lower labor costs.

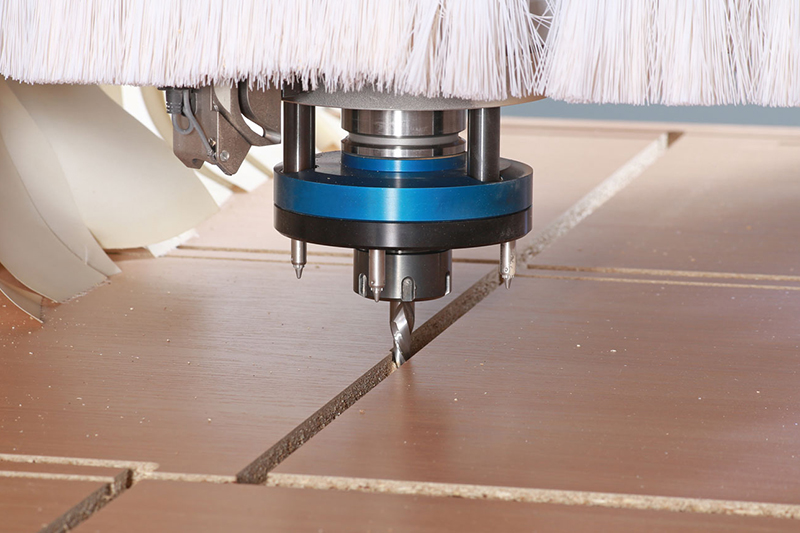

- Precision: Modern multi-boring machines are equipped with advanced technology that allows for precise positioning and drilling of holes. This accuracy ensures that the holes are consistently placed according to the required specifications, leading to high-quality end products.

- Versatility: Multi-boring machines can be configured to drill holes of various sizes, depths, and orientations, making them suitable for a wide range of woodworking applications. They can be used to drill dowel holes, hinge cup holes, shelf pin holes, and more, providing versatility in furniture construction.

- Consistency: With multi-boring machines, each hole is drilled with the same parameters, ensuring consistency across multiple workpieces. This uniformity is crucial for maintaining the structural integrity and aesthetic appeal of the final product.

- Reduced Waste: By accurately drilling holes in the correct locations, multi-boring machines help minimize material waste. This is especially important when working with expensive or limited resources, such as solid wood or high-quality plywood.

- Automation Potential: Some multi-boring machines can be integrated into automated production lines, further streamlining the manufacturing process and reducing the need for manual labor. This automation can lead to increased output and cost savings over time.

- Ease of Operation: Many modern multi-boring machines feature user-friendly interfaces and programmable settings, making them easy to operate even for inexperienced operators. This accessibility allows woodworking businesses to quickly train new employees and maintain consistent production standards.

Overall, multi-boring machines offer numerous advantages in terms of efficiency, precision, versatility, consistency, waste reduction, automation potential, and ease of operation, making them an indispensable tool in the woodworking industry.