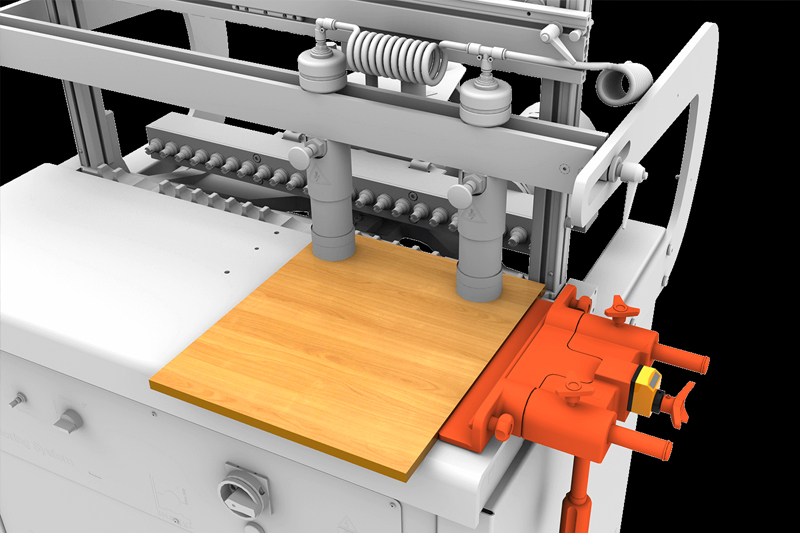

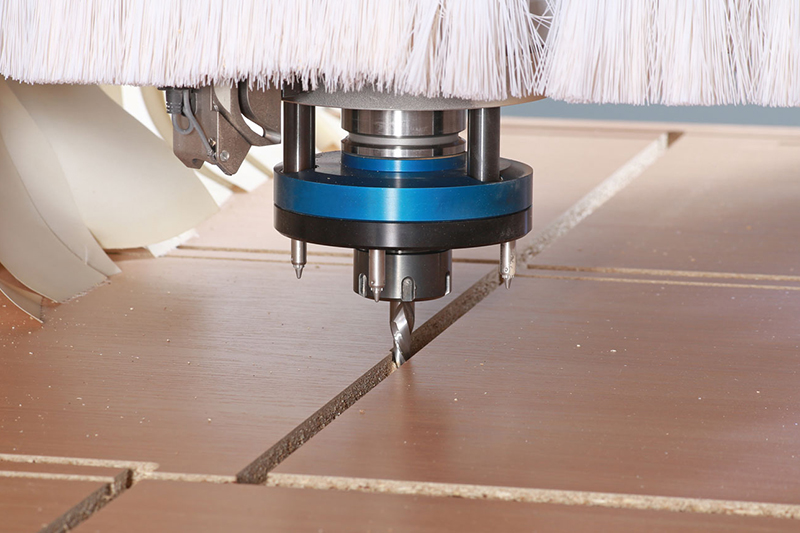

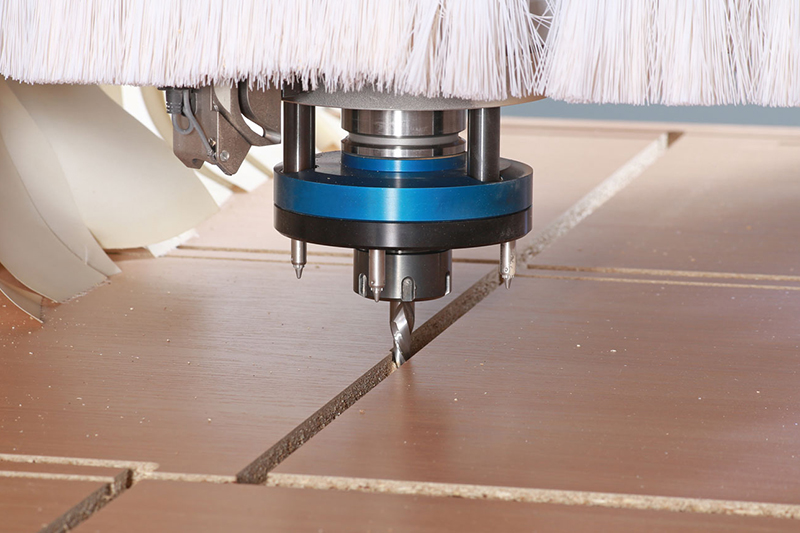

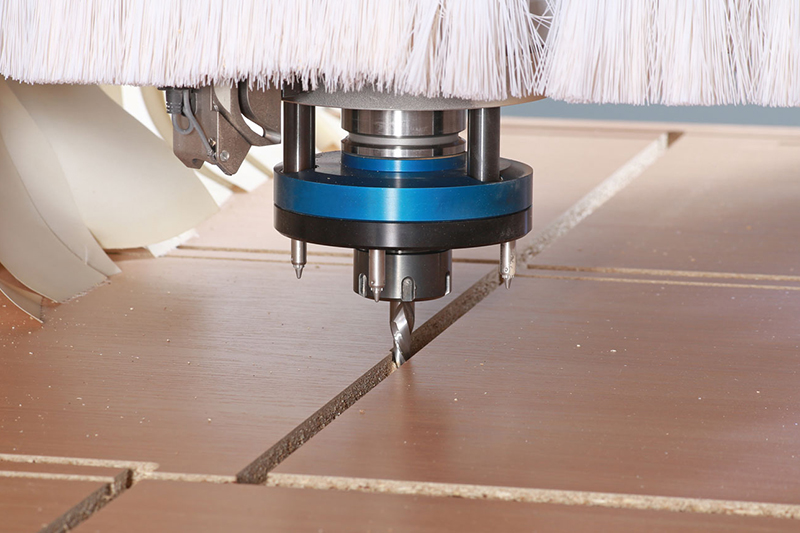

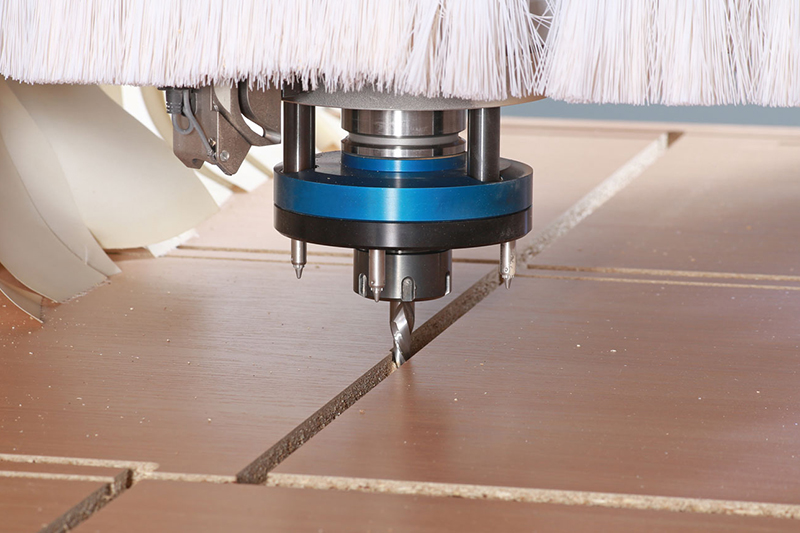

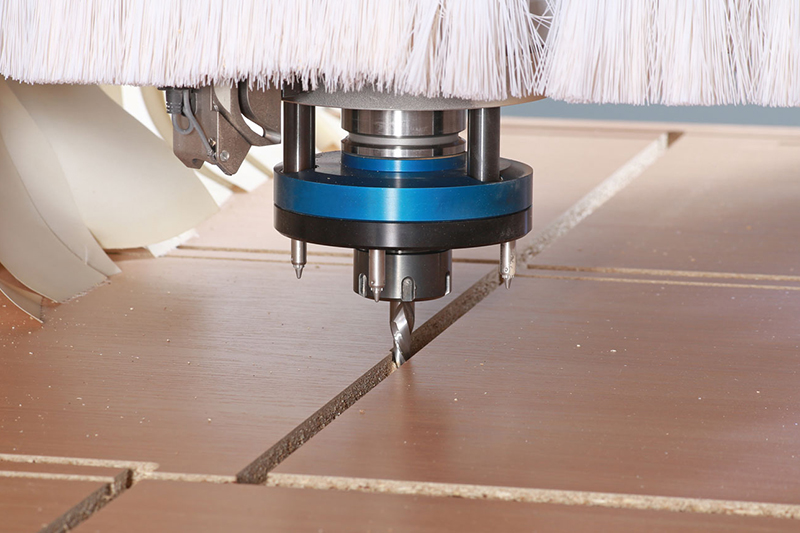

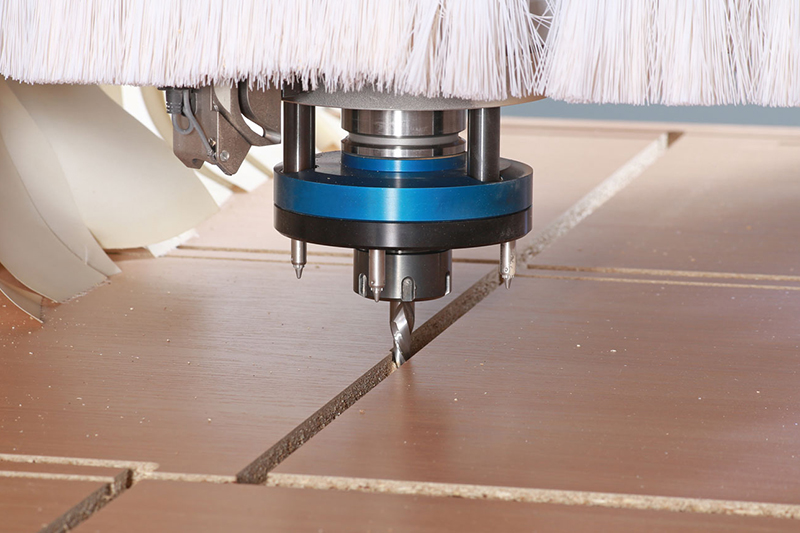

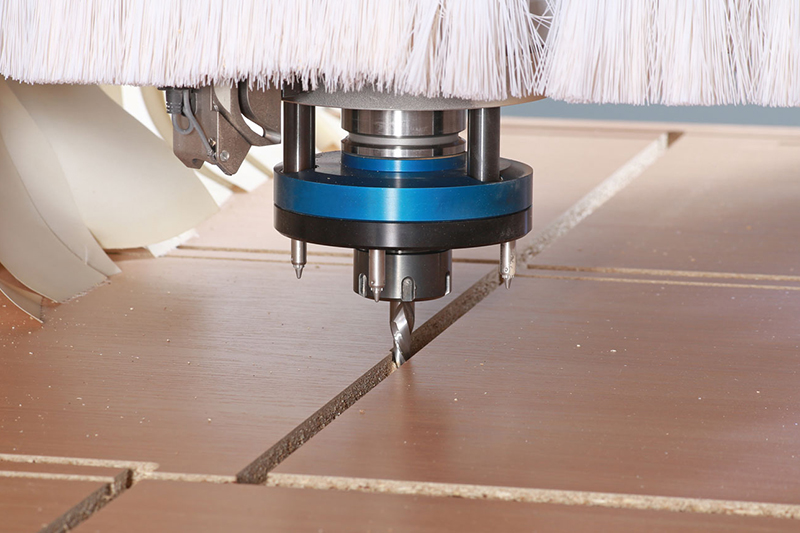

Carving

Benefits of Edge Banding in Furniture Manufacturing

- Enhanced Aesthetics: Edge banding gives furniture pieces a clean and finished look by covering the exposed edges of panels with a matching or contrasting material. This improves the overall appearance of the furniture and enhances its aesthetic appeal, making it more attractive to customers.

- Durability and Protection: Edge banding helps protect the edges of furniture panels from damage, such as chipping, moisture absorption, and wear and tear. By covering these vulnerable areas with a durable material like PVC, ABS, or wood veneer, edge banding extends the lifespan of furniture pieces and maintains their structural integrity.

- Seamless Joints: Edge banding creates seamless joints between adjacent panels, resulting in a smooth and uniform surface. This not only improves the visual appeal of the furniture but also enhances user experience by eliminating sharp edges and rough surfaces.

- Versatility: Edge banding can be applied to various types of materials, including plywood, particle board, MDF, and even solid wood. This versatility allows furniture manufacturers to use edge banding in a wide range of applications, from residential furniture to commercial and industrial projects.

Overall, the edge banding process offers numerous advantages in furniture manufacturing, including enhanced aesthetics, durability, seamless joints, customization options, cost-effectiveness, efficiency, versatility, and ease of maintenance. It is an essential technique for achieving high-quality, finished products that meet the needs and expectations of customers.